In my blog about my experience at Northwest Nomads, I talked about how the TW was experiencing engine issues. Long before the festival, I was hearing excessive valve clatter every few days, and had to adjust the intake valve every single time. Even though I knew about this issue, I still opted to ride the TW out, as I thought that the issue was the locking nut on the adjuster screw was coming loose, so I used some threadlocker to prevent vibrations from loosening the screw. We rode out to the event, and when we arrived, my valves were clattering harder than ever before. We took the covers off, and measured the clearances. The intake valve was a good centimeter out of spec, when it should have been 10ths of a millimeter in clearance.

At the festival, we ran into a mechanic who lived on the road with his family. He was kind enough to loan me some tools so I could take the head off, and further inspect what was going on. He believed that the valve had loosened from its keeper, and that he could use a valve spring compressor to push the valve down, so we could adjust the keepers. Even though I didn’t have a new head gasket with me, I opted to try this, and hope for the best. Otherwise I could likely have been stranded there.

The head was removed, and the valve situation was assessed. We couldn’t fix the issue at the event, as the top of the valve’s stem had been hammered hard by the adjuster screw, damaging both the stem and the screw. The hammering effect had either caused, or was caused by the valve slipping through the keepers, and slowly making its way into the head. There really wasn’t any way to remove the valve from the head, as I would have to grind the top of the stem enough to slip it through the valve guide. The mechanic and I reassembled my head. I tried riding back home, but I began experiencing heavy backfiring, and bogging down just outside of La Pine. After making it home, I tore the head apart again, and replaced the intake valve, and the keepers.

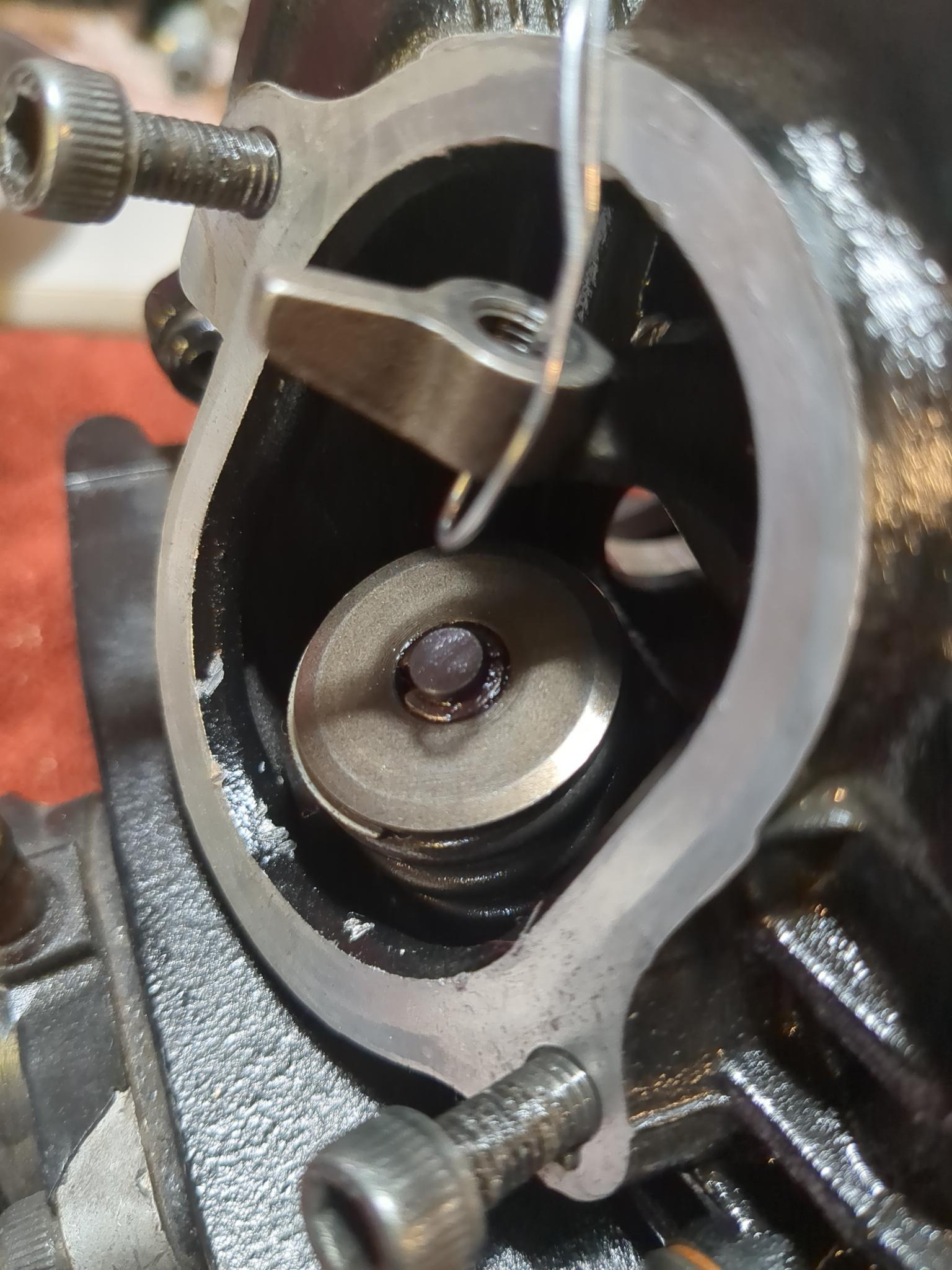

This is the exhaust valve, and what it should look like on top. The stem sticks through the middle of the spring assembly, and is perfectly flat and smooth. The keepers are those two half moon metal pieces just around the stem of the valve.

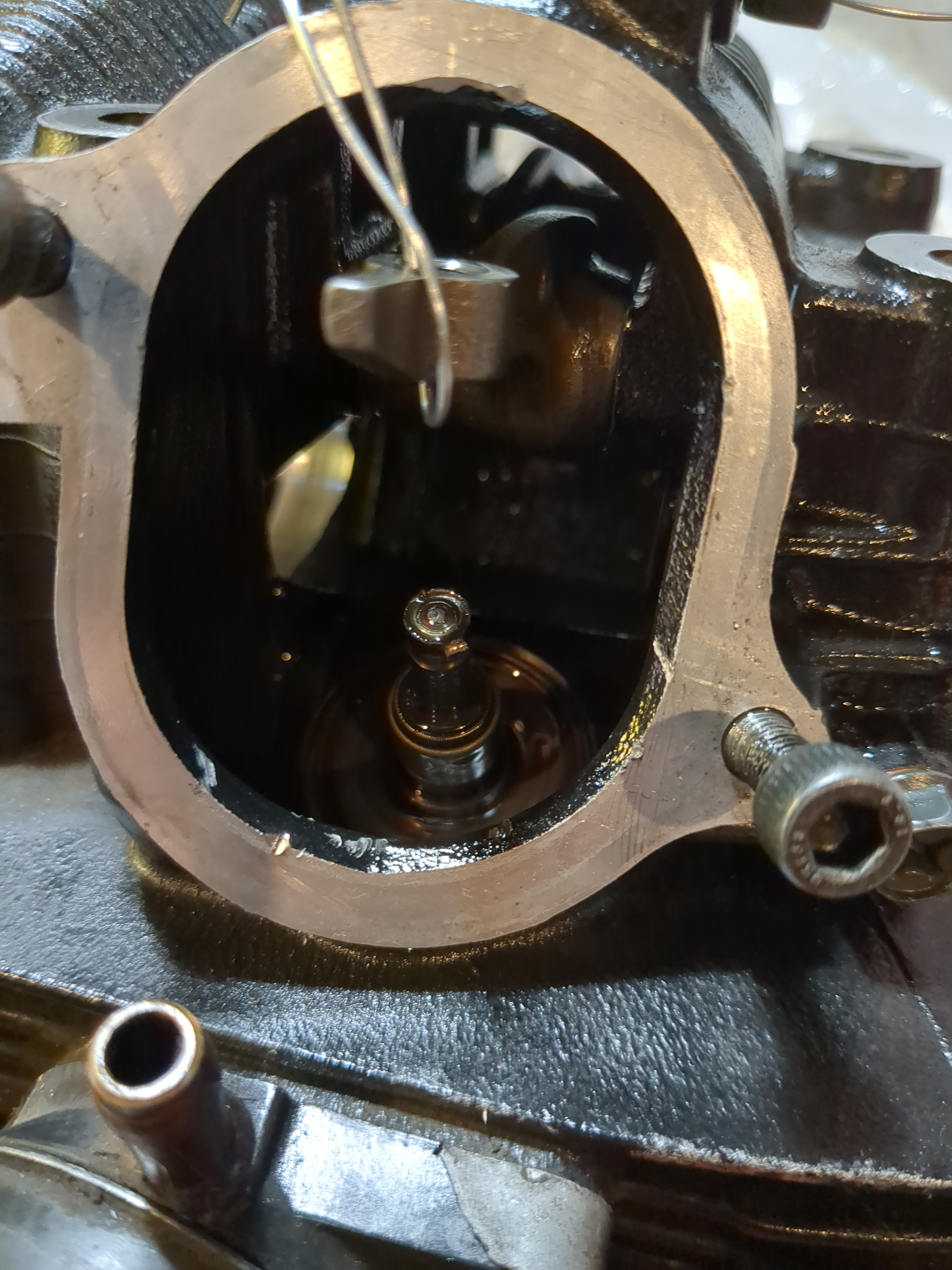

The intake side valve. Notice how the top of the stem has been pounded down, and no longer sticks above the keepers or the spring assembly. I removed the camshaft by using a slide hammer to pound it out.

The valve spring compressor compressing the spring assembly. I broke a cheap one I ordered off of eBay. More on that later. This is a Harbor Freight tool.

What the valve stem looks like with the spring assembly removed. The sides of the stem were pounded down. One side had a spur of metal sticking out, preventing the valve from slipping through the valve guide. I had to take a dremal tool, and grind off the mushroomed top and the spur, so I could pull the valve.

The tappet/adjuster screw. This is the bottom side, which is what contacts the stem of the valve. As you can see, it has taken quite a beating. I’m going to replace it with a new screw, however I’m using this one temporarily, as I didn’t have a spare on hand.

The valve on the left is the one I took out, and the valve on the right is the valve I sucked into the engine a few years ago. They both happen to be the intake valve, which has me wondering if there’s some sort of issue where intake valves on TW’s are more likely to fail. It’s a trend I’ve noticed online. Having a sample size of two, some anecdotal evidence from reading random forum posts, and watching a youtuber take his own intake valve out on his XT-225 (same engine), is not enough to draw a conclusion over. However, I will be watching that intake valve diligently.

Intake valve installed. One difference I noticed between the exhaust and the intake valve, is that the keepers on the exhaust valve fit symmetrically around the stem. Whereas with the intake, they don’t fit symmetrically, and there’s a slight gap between the keepers. My manual has a similar looking picture, but I wonder if that has anything to do with the valves getting mushroomed. Who knows? I’m not an engineer, and I’m just postulating.

The spring compressor on the left is a cheap eBay one I purchased for $15, and the tool on the right is a Harbor Freight $50 compressor. Harbor Freight wins again.

I went on to reinstall the head, new head gaskets, and exhaust. The bike fired up, yet was still running pretty poorly. I tested it over a few days, and concluded that it was running rich, as the spark plug was black and sooty, and it was bogging down at high RPM’s. I messed with the carburetor and valve clearances, believing that I messed up some adjustment. I even went on to fully disassemble the carb, clean it, and set it back to the factory air/fuel mixture screw setting. As I was riding around, I noticed a slight popping noise, and some electrical clicks. I changed the spark plug, thinking that the plug was faulty. The same issue kept occurring. I narrowed it down to the ignition coil, which I had replaced years ago, believing the OEM one was faulty. I was cheap at the time, and purchased an aftermarket ignition coil. I kept the old one, as I keep old part in case I ever need to cannibalize them. I threw the old one on, and it worked perfectly. Don’t buy cheap aftermarket parts.

The aftermarket coil. The rubber boots were cheaply made, and falling apart. As I stated above, don’t buy cheap after market parts.

Finally, I had some heat wrap laying around. I decided that I didn’t like the look of my rusted exhaust. So I went about wrapping the exhaust. It wasn’t the best job, but I don’t really care. I actually like how unprofessional it looks; It belies the nature of the TW as a bike cobbled together, and worked on in the field under austere conditions. Plus, it should help with the engine heat a little, it’ll keep the exhaust warm, helping with engine efficiency a little. The exhaust sounds better, although that could just be me projecting.

The exhaust before the wrap. The header (the pipe directly connected to the engine) has some serious discoloration.

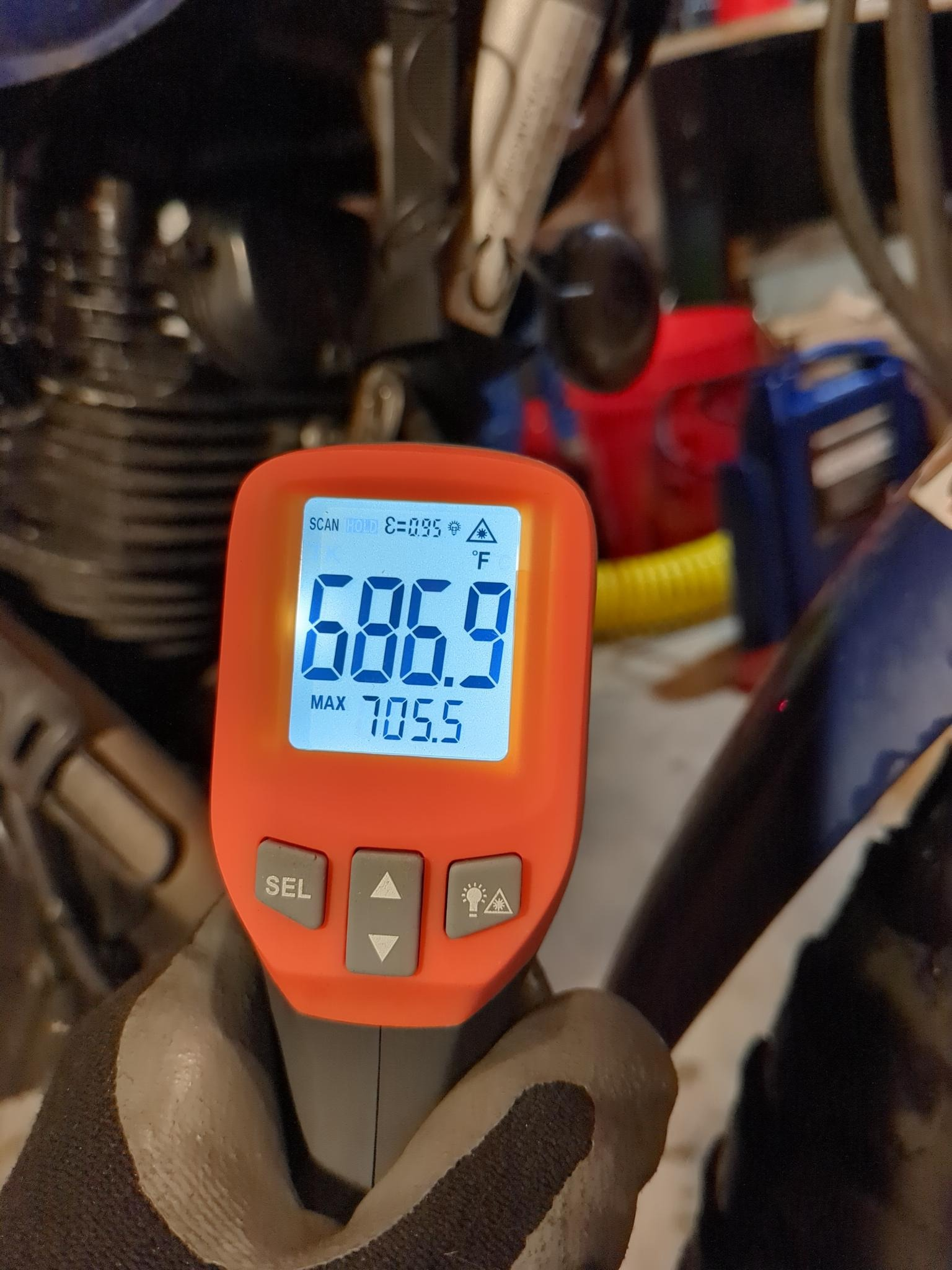

The exhaust was peaking at just over 700 F, and while the pipe isn’t that hot the whole way through, I figured heat wrapping it would help keep the heat away from me, as well as my engine, and inside the exhaust. Dirty Garage Guy explains pretty succinctly what heat wrapping does.

The pipes fully removed from the bike. There’s quite a bit of rust on them.

Header wrapped. Technically this is the only part of the exhaust that actually needs to be wrapped, as the muffler/catalytic converter has some amount of insulation, and does not get nearly as hot as the headers. However, I decided to wrap that as well.

The entirety of the pipes wrapped. I had a few issues with the wrap, such as being unable to wrap the joint where the headers and the muffler meet, as wrapping them would require removing the entire exhaust if I wanted to work on the head, which I really don’t want to do. Also, the two spots where the muffler mounts to the frame had some difficulties. The rear mount by the actual tailpipe is obscured by the fairing of the bike, but there is one spot that is exposed, and not covered by the fairing. This is my first wrap, and I did not expect it to be perfect. But like I said, I like the cobble together aspect of the TW, and the fact that the wrap isn’t perfect, just adds to that.

The wrap on the bike. As I keep saying, it doesn’t look pretty. However, I really like how it came out. And the exhaust temp is now only in the high 200’s (I forgot to snap a picture, maybe I’ll add one later). The exhaust also sounds slightly better, though that might just be me thinking it sounds better. It has a throatier sound to it.

All said and done, the TW went through a fairly massive overhaul. One of the reasons I really like the TW, and use it basically as a commuter bike, is that you can literally do anything with it, go anywhere, and there really isn’t much on the bike that you can’t work on yourself, or teach yourself. As I keep hammering on about, the TW is one of the last true “do it yourself” production bikes, and it’s expected that you’re going to do a lot of the maintenance and upgrades yourself. There’s a massive aftermarket scene for TW parts and upgrades. Because TW owners are borderline cultists, there’s a massive fanbase of riders who’ve done every sort of upgrade, or encountered a mechanical problem that the community engaged with. I even found someone who pulled the ultimate madlad move and turbo’d a TW. He basically turbo’d a push lawnmower.