I’ve been fairly busy recently, so instead of making a bunch of posts about all the vehicle I fixed up, I’d give a quick recap of everything I fixed:

Today I replaced the ignition cylinder on a 2012 Volkswagen Tiguan. The vehicle is a friend of a friend, and somehow the ignition cylinder, the metal thing that the key lock attaches to, jammed up. Apparently this is a common problem with Volkswagen’s or German vehicles in general, as the replacement part had Audi, Mercedez, BMW, and Volkswagen marks on it. I took the cylinder off, and had to separate the key lock from the cylinder, which required rotating the lock, and using a pin to press on a tab to release it. Since the cylinder was jammed, and I couldn’t rotate the lock, I did what anyone with no idea what they were doing would do, and just hit the ever living jesus out of the cylinder with a hammer until the lock turned. After that, install was a breeze, although remembering the wire routing was a little confusing. Always take pictures or make drawings of the wire routing, and which wire plugs into where.

My friend Jamie has a 2012 Kawasaki Versys. For her birthday, I did a mostly full riding season prep for the bike, which hasn’t been ridden since before the beginning of fall last year. That involved an oil change, coolant change, brake fluid flush, a drive chain cleaning, and an overall washing of the bike, which was covered in spider webs. I also filled the tires, measured the tires, and tested and charged the battery. All said and done, the bike rides well. I overfilled the coolant a little, there was a lot of air in the system when I swapped the coolant, and I’m pretty sure there’s an overflow bottle somewhere that I did not drain. While she was riding, some coolant shot out of a drain hose, which scared her a little. However, the coolant bottle is still relatively full, so like I said, I probably didn’t drain an overflow bottle.

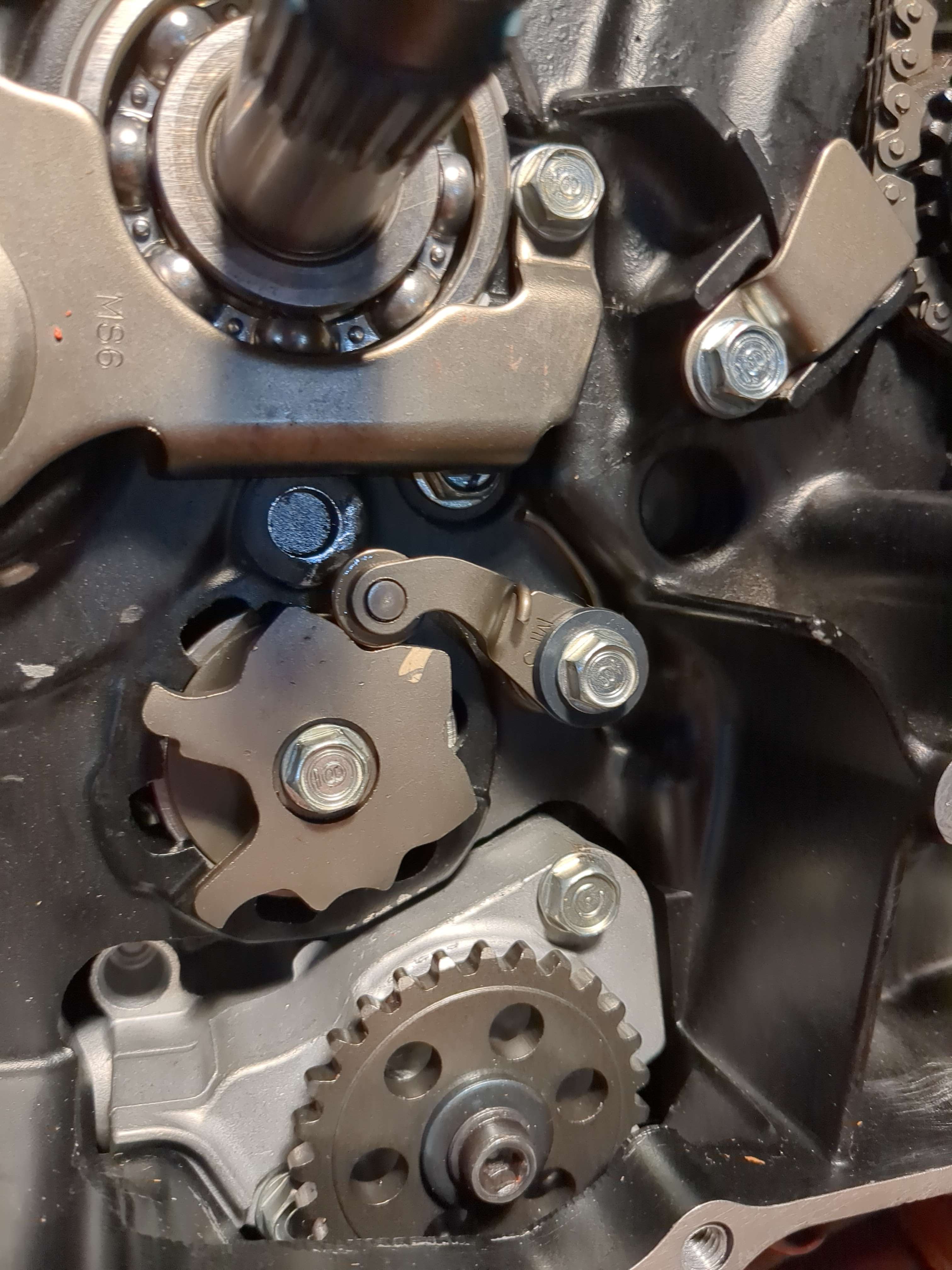

I installed the shift mechanism on the Shadow. In the picture below, it’s the start shaped thing with the little arm with the round circle thing resting inside one of the grooves. How it works is the shift lever is pushed up or down by your foot, which pushes some pins located on the inside side of the mechanism to be pushed up or down. This rotates the star, which is connected to the shift drum, which rotates and moves the shift forks, which moves the gears of the transmission. Here is a video of how it works from the shift lever to the transmission itself. It does a good job illustrating how a constant mesh transmission works. However, I disagree with it saying that “Drivers need tremendous skill to operate it”. I’d argue that a CMT is far easier to operate and maintain/rebuild than a regular manual H transmission that are found in cars.